![]()

|

|||||||||||||||||||||||||

Specifications |

| 1. uPVC Pipes for Drinking Water Service with Both Plain End (in arctic blue color) | |

| For portable water supply and distribution, drainage, and sewerage. | |

|

Manufactured in conformity with TIS. 17-2532 "Standard for Unplasticized Polyvinyl Chloride Pipes for Drinking Water Service." |

| Unit: mm |

| Nominal Size | Outside Diameter | Thickness | Length |

Weight per Length (Kg) |

||||

| PVC 5 | PVC 8.5 | PVC 13.5 | PVC 5 | PVC 8.5 | PVC 13.5 | |||

| 18 (½") | 22±0.15 | - | 2.0±0.20 | 2.5±0.20 | +30 4000 -0 |

- | 0.72 | 0.88 |

| 20 (¾") | 26±0.15 | - | 2.0±0.20 | 2.5±0.20 | - | 0.86 | 1.06 | |

| 25 (1") | 34±0.15 | - | 2.0±0.20 | 3.0±0.25 | - | 1.15 | 1.67 | |

| 35 (1¼") | 42±0.15 | 1.5±0.15 | 2.0±0.20 | 3.1±0.25 | 1.09 | 1.44 | 2.17 | |

| 40 (1½") | 48±0.15 | 1.5±0.15 | 2.3±0.20 | 3.5±0.25 | 1.25 | 1.89 | 2.80 | |

| 55 (2") | 60±0.15 | 1.8±0.20 | 2.9±0.25 | 4.3±0.30 | 1.88 | 2.98 | 4.30 | |

| 65 (2½") | 76±0.20 | 2.2±0.20 | 3.5±0.25 | 5.4±0.35 | 2.92 | 4.56 | 6.85 | |

| 80 (3") | 89±0.20 | 2.5±0.20 | 4.1±0.30 | 6.4±0.40 | 3.89 | 6.26 | 9.50 | |

| 100 (4") | 114±0.30 | 3.2±0.25 | 5.2±0.35 | 8.1±0.50 | 6.37 | 10.17 | 15.41 | |

| 125 (5") | 140±0.30 | 3.9±0.30 | 6.4±0.40 | 9.9±0.55 | 9.55 | 15.40 | 23.23 | |

| 150 (6") | 165±0.40 | 4.6±0.30 | 7.5±0.45 | 11.7±0.65 | 13.28 | 21.29 | 32.37 | |

| 200 (8") | 216±0.50 | 5.4±0.35 | 8.8±0.50 | 13.7±0.75 | 20.48 | 32.87 | 50.06 | |

| 250 (10") | 267±0.70 | 6.6±0.40 | 10.9±0.60 | 16.9±0.90 | 30.96 | 50.37 | 76.43 | |

| 300 (12") | 318±0.80 | 7.8±0.45 | 12.9±0.70 | 20.1±1.05 | 43.61 | 71.07 | 108.40 | |

| 350 (14") | 370±0.90 | 9.1±0.55 | 15.0±0.80 | 23.4±1.20 | 59.22 | 96.22 | 147.01 | |

| 400 (16") | 420±1.10 | 10.3±0.60 | 17.0±0.90 | 26.5±1.35 | 76.12 | 123.89 | 189.23 | |

| 450 (18") | 470±1.20 | 11.5±0.65 | 19.0±1.00 | 29.7±1.50 | 95.16 | 155.07 | 237.58 | |

| 500 (20") | 520±1.30 | 12.7±0.70 | 21.0±1.10 | 32.8±1.65 | 116.32 | 189.78 | 290.65 | |

| 600 (24") | 630±1.60 | 15.3±0.80 | 25.4±1.30 | 39.7±2.00 | 169.97 | 278.57 | 427.32 | |

| Note: |

| 1. Working pressures of PVC pipes class PVC 5, PVC 8.5 and PVC 13.5 are 5, 8.5 and 13.5 kgf/cm2 at 27ºC respectively. |

| 2. Pipe length differs from the standard 4000 mm can be made. Please contact our sales department for special arrangement. |

| 3. Weight per length in the table above are approximated values. |

| 2. uPVC Pipes for Industrial Use with Both Plain End (in grey color) | |

| For industrial use such as irrigation, drainage, and sewerage & vent. | |

|

Manufactured in conformity with TIS. 999-2533 "Standard for Unplasticized Polyvinyl Chloride Pipes for Industrial Use." |

| Unit: mm |

| Nominal Size | Outside Diameter | Thickness | Length |

Weight per Length (Kg) |

||||||

| PVC 0 | PVC 5 | PVC 8.5 | PVC 13.5 | PVC 0 | PVC 5 | PVC 8.5 | PVC 13.5 | |||

| 15 (3/8") | 18±0.15 | - | - | - | 2.0±0.20 | +30 4000 -0 |

- | - | - | 0.58 |

| 18 (½") | 22±0.15 | - | - | 2.0±0.20 | 2.5±0.20 | - | - | 0.72 | 0.88 | |

| 20 (¾") | 26±0.15 | - | - | 2.0±0.20 | 2.5±0.20 | - | - | 0.86 | 1.06 | |

| 25 (1") | 34±0.15 | - | - | 2.0±0.20 | 3.0±0.25 | - | - | 1.15 | 1.67 | |

| 35 (1¼") | 42±0.15 | - | 1.5±0.15 | 2.0±0.20 | 3.1±0.25 | - | 1.09 | 1.44 | 2.17 | |

| 40 (1½") | 48±0.15 | - | 1.5±0.15 | 2.3±0.20 | 3.5±0.25 | - | 1.25 | 1.89 | 2.80 | |

| 55 (2") | 60±0.15 | - | 1.8±0.20 | 2.9±0.25 | 4.3±0.30 | - | 1.88 | 2.98 | 4.30 | |

| 65 (2½") | 76±0.20 | 2.0±0.20 | 2.2±0.20 | 3.5±0.25 | 5.4±0.35 | 2.66 | 2.92 | 4.56 | 6.85 | |

| 80 (3") | 89±0.20 | 2.0±0.20 | 2.5±0.20 | 4.1±0.30 | 6.4±0.40 | 3.13 | 3.89 | 6.26 | 9.50 | |

| 100 (4") | 114±0.30 | 2.5±0.20 | 3.2±0.25 | 5.2±0.35 | 8.1±0.50 | 5.01 | 6.37 | 10.17 | 15.41 | |

| 125 (5") | 140±0.30 | 2.8±0.20 | 3.9±0.30 | 6.4±0.40 | 9.9±0.55 | 6.91 | 9.55 | 15.40 | 23.23 | |

| 150 (6") | 165±0.40 | 3.4±0.25 | 4.6±0.30 | 7.5±0.45 | 11.7±0.65 | 9.88 | 13.28 | 21.29 | 32.37 | |

| 200 (8") | 216±0.50 | 3.4±0.25 | 5.4±0.35 | 8.8±0.50 | 13.7±0.75 | 12.99 | 20.48 | 32.78 | 50.06 | |

| 250 (10") | 267±0.70 | 3.4±0.25 | 6.6±0.40 | 10.9±0.60 | 16.9±0.90 | 16.11 | 30.96 | 50.37 | 76.43 | |

| 300 (12") | 318±0.80 | 3.4±0.25 | 7.8±0.45 | 12.9±0.70 | 20.1±1.05 | 19.23 | 43.61 | 71.07 | 108.40 | |

| 350 (14") | 370±0.90 | 3.9±0.25 | 9.1±0.55 | 15.0±0.80 | 23.4±1.20 | 25.67 | 59.22 | 96.22 | 147.01 | |

| 400 (16") | 420±1.10 | 4.4±0.30 | 10.3±0.60 | 17.0±0.90 | 26.5±1.35 | 32.87 | 76.12 | 123.89 | 189.23 | |

| 450 (18") | 470±1.20 | 5.0±0.35 | 11.5±0.65 | 19.0±1.00 | 29.7±1.50 | - | 95.16 | 155.07 | 237.58 | |

| 500 (20") | 520±1.30 | 5.5±0.35 | 12.7±0.70 | 21.0±1.10 | 32.8±1.65 | - | 116.32 | 189.78 | 290.65 | |

| 600 (24") | 630±1.60 | 6.5±0.40 | 15.3±0.80 | 25.4±1.30 | 39.7±2.00 | - | 169.97 | 278.57 | 427.32 | |

| Note: |

| 1. Working pressures of PVC pipes class PVC 5, PVC 8.5 and PVC 13.5 are 5, 8.5 and 13.5 kgf/cm2 at 27ºC respectively. |

| 2. Pipe length differs from the standard 4000 mm can be made. Please contact our sales department for special arrangement. |

| 3. Weight per length in the table above are approximated values. |

| 4. PVC pipe class PVC 0 is non-pressure pipe which is suitable for air ducting pipe. It is not recommended for the application with external pressure or loading on the pipe. |

| 3. uPVC Pipes for Electrical Wiring and Telephone Cable Conduit with Both Plain End (in yellow color) | |

| For electrical wiring & telephone cable conduit. | |

|

Manufactured in conformity with TIS. 216-2524 "Standard for Rigid PVC Conduit for Electrical Wiring and Telephone Cable." |

| Unit: mm |

| Nominal Size | Outside Diameter | Thickness | Length | Weight per Length (Kg) | ||||

| Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | |||

| 15 (3/8") | 18±0.20 | 2.0±0.20 | - | - | +30 4000 -10 |

0.59 | - | - |

| 18 (½") | 22±0.20 | 2.0±0.20 | - | - | 0.74 | - | - | |

| 20 (¾") | 26±0.25 | 2.0±0.20 | - | - | 0.89 | - | - | |

| 25 (1") | 34±0.30 | 3.0±0.30 | - | - | 1.72 | - | - | |

| 35 (1¼") | 42±0.35 | 3.5±0.40 | - | - | 2.49 | - | - | |

| 40 (1½") | 48±0.40 | 4.0±0.40 | - | - | 3.25 | - | - | |

| 55 (2") | 60±0.50 | 4.5±0.40 | - | - | 4.61 | - | - | |

| 65 (2½") | 76±0.50 | 4.5±0.40 | - | - | 5.94 | - | - | |

| 80 (3") | 89±0.50 | 5.9±0.40 | - | - | 9.06 | - | - | |

| 100 (4") | 114±0.50 | 7.0±0.40 | - | - | 13.84 | - | - | |

| 80 (3") | 89±0.50 | 5.9±0.40 | 4.5±0.30 | 2.5±0.25 | +30 6000 -10 |

13.59 | 10.54 | 5.99 |

| 100 (4") | 114±0.50 | 7.0±0.40 | 5.7±0.35 | 3.0±0.30 | 20.75 | 17.10 | 9.23 |

| Note: |

| 1. Pipe length differs from the standard 4000 mm can be made. Please contact our sales department for special arrangement. |

| 2. Weight per length in the table above are approximated values. |

| 3. Pipe classification is made according to its resistance to compression. |

| 4. uPVC Pipes for Agricultural Use with Both Plain End (in grey color) | |

| For agricultural use & low pressure system. | |

| Manufactured in conformity with "THAI PIPE STANDARD." | |

| Unit: mm |

| Nominal Size | Outside Diameter | Thickness | Length | Weight per Length (Kg) |

| 10 (¼") | 14±0.10 | 1.1±0.10 | +30 4000 -10 |

0.23 |

| 15 (3/8") | 18±0.15 | 1.1±0.10 | 0.33 | |

| 18 (½") | 22±0.15 | 1.1±0.10 | 0.41 | |

| 20 (¾") | 26±0.15 | 1.2±0.10 | 0.53 | |

| 25 (1") | 34±0.15 | 1.2±0.10 | 0.70 | |

| 35 (1¼") | 42±0.15 | 1.3±0.10 | 0.94 | |

| 40 (1½") | 48±0.15 | 1.3±0.10 | 1.08 | |

| 55 (2") | 60±0.15 | 1.5±0.10 | 1.57 | |

| 65 (2½") | 76±0.20 | 1.8±0.10 | 2.38 | |

| 80 (3") | 89±0.20 | 2.3±0.10 | 3.56 | |

| 100 (4") | 114±0.30 | 2.6±0.10 | 5.17 | |

| 125 (5") | 140±0.30 | 3.4±0.20 | 8.29 |

| Note: |

| 1. Pipe length differs from the standard 4000 mm can be made. Please contact our sales department for special arrangement. |

| 2. Weight per length in the table above are approximated values. |

| 5. uPVC Pipes for Tubewell (in grey color) | |

| For application in water wells. | |

| Manufactured in conformity with "THAI PIPE STANDARD." | |

Unit: mm |

| Nominal Size | Outside Diameter | Inside Diameter | Thickness | Length | Weight per Length (Kg) |

| 100 (4") | 120±0.30 | 103.8 | 8.1±0.50 | +30 4000 -10 |

16.29 |

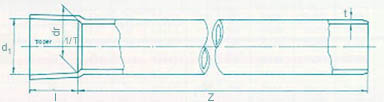

| 6. uPVC Pipes One End with TS Socket | |

|

Manufactured in conformity with TIS. 17-2532 |

Unit: mm |

| Nominal Size | Dimensions of uPVC Pipe One End TS Socket | ||||

| d1 | dr | l | 1/T | Z (min.) | |

| 15 (3/8") | 18.4±0.2 | 17.5±0.3 | 26 | 1/30 | 3,950 |

| 18 (½") | 22.4±0.2 | 21.4±0.3 | 30 | 1/34 | 3,945 |

| 20 (¾") | 26.4±0.2 | 25.3±0.3 | 35 | 1/34 | 3,940 |

| 25 (1") | 34.6±0.2 | 33.3±0.3 | 41 | 1/34 | 3,935 |

| 35 (1¼") | 42.6±0.2 | 41.2±0.3 | 46 | 1/34 | 3,930 |

| 40 (1½") | 48.7±0.3 | 47.2±0.4 | 55 | 1/37 | 3,920 |

| 55 (2") | 60.8±0.3 | 59.0±0.4 | 63 | 1/37 | 3,910 |

| 65 (2½") | 76.6±0.3 | 75.2±0.4 | 63 | 1/48 | 3,910 |

| 80 (3") | 89.6±0.3 | 88.2±0.4 | 64 | 1/49 | 3,905 |

| 100 (4") | 114.7±0.3 | 113.2±0.4 | 84 | 1/56 | 3,885 |

| 125 (5") | 140.8±0.4 | 139.0±0.4 | 104 | 1/58 | 3,860 |

| 150 (6") | 166±0.4 | 163.9±0.4 | 132 | 1/63 | 3,830 |

| 200 (8") | 217.9±0.8 | 213.8±0.9 | 200 | 1/50 | 3,750 |

| 250 (10") | 269.3±0.9 | 264.2±1.0 | 250 | 1/50 | 3,700 |

| 300 (12") | 320.7±1.0 | 314.6±1.1 | 300 | 1/50 | 3,645 |

| 350 (14") | 373.1±1.0 | 366.0±1.1 | 350 | 1/50 | 3,595 |

| 400 (16") | 423.6±1.2 | 415.5±1.3 | 400 | 1/50 | 3,540 |

| 450 (18") | 474.0±1.2 | 464.9±1.3 | 450 | 1/50 | 3,490 |

| 500 (20") | 524.5±1.3 | 514.4±1.4 | 500 | 1/50 | 3,435 |

| 600 (24") | 635.3±2.1 | 623.2±2.2 | 600 | 1/50 | 3,330 |

| Note: |

| 1. Tolerance 'l' for size 18-150 mm is ±50 mm and for 200-600 mm is ±100 mm. |

| 2. "Z" is the effective length made from both plain end pipe of 4,000 mm length. |

| 3. "t" depends on the size and class of fabricated pipe. |

6. uPVC Pipes One End w

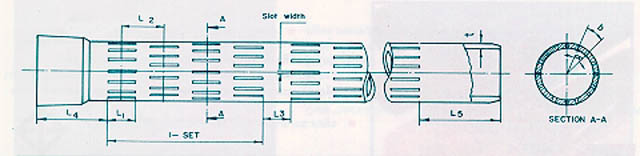

| 7. uPVC Screen Pipe |

| 7.1 Slotted uPVC Screen Pipe |

Unit: mm |

| Nominal Size | L1 | L2 | L3 | L4 | L5 | Slot Width | b | No. of Slot on the Same Circumference | No. of Set per Length (4.00 m) | Approx. Opening Area | |

| 55 (2") | 80±10 | 120±10 | 80±10 | 215 | 220 | 2.4±0.2 | 45º | 23.5 | 8 | 7 | 5.7% |

| 65 (2½") | 80±10 | 120±10 | 80±10 | 215 | 220 | 2.4±0.2 | 36º | 23.9 | 10 | 7 | 5.6% |

| 80 (3") | 80±10 | 120±10 | 80±10 | 210 | 220 | 2.4±0.2 | 30º | 23.3 | 12 | 7 | 5.8% |

| 100 (4") | 80±10 | 120±10 | 80±10 | 210 | 220 | 2.4±0.2 | 22.5º | 22.4 | 16 | 7 | 6.0% |

| 125 (5") | 80±10 | 120±10 | 80±10 | 205 | 220 | 2.4±0.2 | 20º | 24.4 | 18 | 7 | 5.5% |

| 150 (6") | 80±10 | 120±10 | 80±10 | 200 | 220 | 2.4±0.2 | 18º | 25.9 | 20 | 7 | 5.2% |

| 200 (8") | 130±10 | 205±10 | 75±10 | 450 | 320 | 2.4±0.2 | 15º | 28.3 | 24 | - | 4.4% |

| 250 (10") | 120±10 | 210±10 | 90±10 | 395 | 335 | 2.4±0.2 | 12.9º | 30.0 | 28 | - | 3.8% |

| 300 (12") | 140±10 | 210±10 | 55±10 | 380 | 360 | 2.4±0.2 | 12.9º | 33.3 | 30 | - | 7.0% |

| Note: |

| 1. Standard length of "Slotted uPVC Screen Pipe" is 4000 mm.. |

| 2. "t" depends on the size and class of fabricated pipe. |

| 3. For slot width differed from above table, please contact our sales department. |

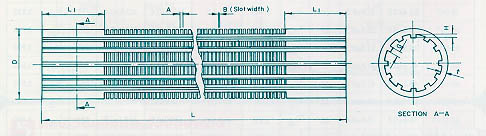

| 7.2 Spiral Slot uPVC Screen Pipe |

Unit: mm |

Nominal Size |

D | t | L | L1 | H | G | Type 1 | Type 2 | No. of Ribs | Approx. Opening Area | |||

| A | B | A | B | Type 1 | Type 2 | ||||||||

| 40 (1½") | 48±0.15 | 3.5±0.25 | +30 1000 -0 |

50±10 | 2.5±0.5 | 5±1 | 2.0±0.2 | 1.0±0.2 | 4.0±0.2 | 0.5±0.1 | 6 | 24.0% | 8.0% |

| 55 (2") | 60±0.15 | 4.3±0.30 | 55±10 | 3.0±0.5 | 6±1 | 2.0±0.2 | 1.0±0.2 | 4.0±0.2 | 0.5±0.1 | 6 | 24.0% | 8.0% | |

| 100 (4") | 114±0.30 | 8.1±0.50 | 100±10 | 4.0±0.5 | 6±1 | 2.0±0.2 | 1.0±0.2 | 4.0±0.2 | 0.5±0.1 | 12 | 21.3% | 7.1% | |

| 125 (5") | 140±0.30 | 9.9±0.55 | 110±10 | 5.0±0.5 | 8±1 | 2.0±0.2 | 1.0±0.2 | 4.0±0.2 | 0.5±0.1 | 12 | 20.3% | 6.8% | |

| Note: For different distance between the slots (A) and the size of slot width (B) from above table, please contact our sales department. |

| Features |

|

|

|

|

|

|

|

|

|

|

|

![]() for more info, please contact: info@thaipipe.com.

for more info, please contact: info@thaipipe.com.

Tel: (662) 424-9440,

433-0021, 433-0034, 883-3175

Fax: (662) 433-5264, 433-8358, 433-5266, 424-7856, 883-3109

Address: 441 Somdet Phrapinklao Road, Bangplad, Bangkok 10700, Thailand