![]()

Applications |

Class* |

Color |

|

|---|---|---|---|

Residential |

Household water supply |

PVC 5, PVC 8.5, PVC 13.5 |

Blue |

Industrial |

General industrial applications |

PVC 5, PVC 8.5, PVC 13.5 |

Grey |

*The numbers (in kg/cm2) indicate the highest pressure the pipes can withstand for a continuous period of time at 27°C or 80.6°F.

| Specifications |

| uPVC Pipe for Drinking Water (in arctic blue color) | uPVC Pipe for Industrial Use (in grey color) | ||

Conforming to TIS.17-2532 |

|

Conforming to TIS.999-2533 |

|

| "Standard for Unplasticized Polyvinyl Chloride Pipes for Drinking water Services" | "Standard for Unplasticized Polyvinyl Chloride Pipes for Industrial Use" | ||

Unit: mm |

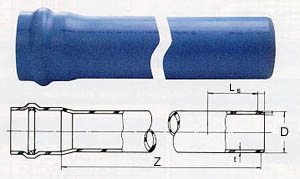

| Nominal Size | Outside Diameter | Thickness | Length Z |

Depth Mark | Weight per Piece (Kg) | ||||

| PVC 5 | PVC 8.5 | PVC 13.5 | Ls | PVC 5 | PVC 8.5 | PVC 13.5 | |||

| 55 (2") | 60±0.15 | 1.8±0.20 | 2.9±0.25 | 4.3±0.30 | +30 6000 -0 |

100 | 2.89 | 4.59 | 6.84 |

| 65 (2½") | 76±0.20 | 2.2±0.20 | 3.5±0.25 | 5.4±0.35 | 105 | 4.50 | 7.04 | 10.58 | |

| 80 (3") | 89±0.20 | 2.5±0.20 | 4.1±0.30 | 6.4±0.40 | 110 | 6.01 | 9.70 | 14.71 | |

| 100 (4") | 114±0.30 | 3.2±0.25 | 5.2±0.35 | 8.1±0.50 | 135 | 9.90 | 15.80 | 23.97 | |

| 150 (6") | 165±0.40 | 4.6±0.30 | 7.5±0.45 | 11.7±0.65 | 155 | 20.69 | 33.14 | 50.56 | |

| 200 (8") | 216±0.50 | 5.4±0.35 | 8.8±0.50 | 13.7±0.75 | 170 | 32.02 | 51.38 | 78.47 | |

| 250 (10") | 267±0.70 | 6.6±0.40 | 10.9±0.80 | 16.9±0.90 | 195 | 48.69 | 79.16 | 120.70 | |

| 300 (12") | 318±0.80 | 7.8±0.45 | 12.9±0.70 | 20.1±1.05 | 220 | 68.97 | 112.32 | 172.11 | |

| 350 (14") | 370±0.90 | 9.1±0.55 | 15.0±0.80 | 23.4±1.20 | 235 | 93.92 | 152.48 | 233.96 | |

| 400 (16") | 420±1.10 | 10.3±0.60 | 17.0±0.90 | 26.5±1.35 | 275 | 121.53 | 197.60 | 303.06 | |

| 450 (18") | 470±1.20 | 11.5±0.85 | 19.0±1.00 | 29.7±1.50 | 285 | 153.07 | 249.17 | 383.57 | |

| 500 (20") | 520±1.30 | 12.7±0.70 | 21.0±1.10 | 32.8±1.65 | 300 | 188.35 | 306.89 | 472.17 | |

| 600 (24") | 630±1.60 | 15.3±0.80 | 25.4±1.30 | 39.7±2.00 | 340 | 278.06 | 454.89 | 701.26 | |

| Note: |

| 1. Working pressures of PVC pipes class PVC 5, PVC 8.5 and PVC 13.5 are, 8.5 and 13.5 kgf/cm2 at 27ºC respectively. |

| 2. Pipe length differs from the standard 6000 mm can be made. Please contact our sales department for special arrangement. |

| 3. Weight per length in the table above are approximated values. |

|

| 1. Improved Strength at Rubber Ring Socket |

| "Thai Pipe" rubber ring pipes are produced by state of the art technology. Pipes are connected by rubber ring provided at the socket. The general understanding is that any expanded portion of a plastic pipe has a thinner wall than the rest of the pipe wall and so has lesser mechanical strength against the interior and exterior pressure due to its reduced cross-section. The "Thai Pipe" rubber ring socket is produced such that its wall thickness is approximately 20-25% thicker than the normal pipe wall. After forming, the socket wall is still thicker than or equal to that of the straight pipe body, thus having sufficient resistance to the interior and exterior pressure. |

| 2. Absolute Water Seal |

| Pipes and pipe joints are connected together by the unique shape rubber ring fitted along the groove in the socket to provide absolute water seal. "Thai Pipe" unique rubber ring design provides the double seal system. The primary (static) seal results from the elasticity of rubber ring and the pipe wall. The secondary (dynamic) seal results from the unique rubber groove design with its efficiency increase along with pressure in the pipe. Thus the joint ensures absolute water seal in every condition, both in positive and negative pressure. |

| 3. Superior Elasticity and Flexibility |

| The "Thai Pipe" rubber ring joint has sufficient flexibility to absorb vibrations caused by uneven ground subsidence or from heavy traffic. The joint has allowable deflection of 3° from pipe axis. Furthermore, it acts like an "Expansion Joint" due to its elasticity to absorb the expansion and shrinkage of the pipe caused by changes in ambient temperature. |

| 4. Quick Installation |

| Speedy installation is obtainable with "Thai Pipe" rubber ring pipes since no adhesive or special tool is required, thus saving cost and time. The piping can be buried immediately after jointed and jointing is easily done by only inserting the pipe into the socket in alignment of the piping axis. Only one person can handle the whole installation by using the jointing jigs. There will be no difference in joint strength which otherwise may result from difference skills of workers. |

| 5. No Ambient Influence |

| The installation of "Thai Pipe" rubber ring pipe is a pushfit insertion joint together with the use of lubricant for rubber ring joint. The system can be installed under any severe natural or geographical conditions, for instance, severe winter season, stormy or floody weather, etc. |

![]() for more info, please contact: info@thaipipe.com.

for more info, please contact: info@thaipipe.com.

Tel: (662) 424-9440,

433-0021, 433-0034, 883-3175

Fax: (662) 433-5264, 433-8358, 433-5266, 424-7856, 883-3109

Address: 441 Somdet Phrapinklao Road, Bangplad, Bangkok 10700, Thailand

[Home] [Company Profile] [Products & Services] [Polywin Doors & WIndows] [Contact Us]